Fiessler Elektronik News

New hydraulic concept

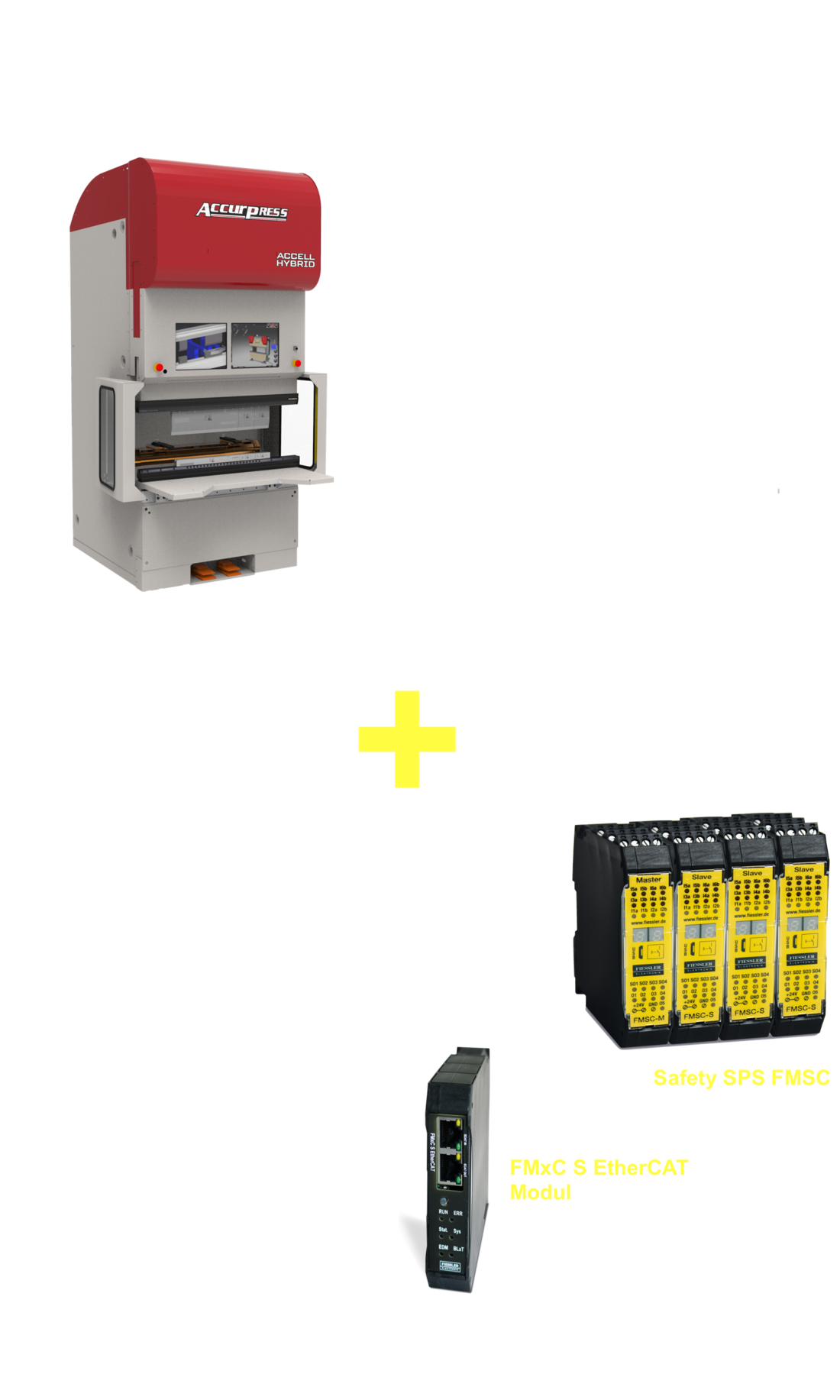

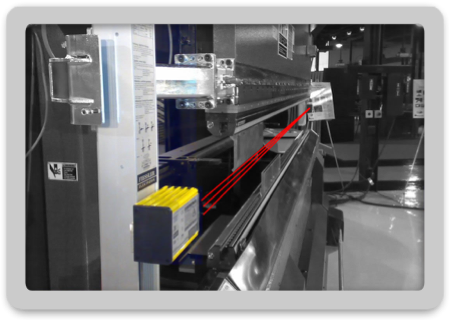

Innovations and new concepts for drive systems in the field of press brakes also require new safety concepts and thus adaptations compared to conventional concept.

This is also the case with the ePrAX® system from HAWE (formerly Hoerbiger)

Together with the well-known press brake manufacturer Accurpress America, Inc. Fiessler Elektronik/Germany developed a safety concept for this new drive system.

New safety concept

Especially the new FMSC supports the adaptation to given drive concepts due to its free programmability and fast cycle times.

ogether with the know-how of Fiessler Elektronik and the respective machine manufacturer, efficient and technically high-quality solutions for press brakes can be developed.

In combination with the new EtherCAT module the mentioned manufacturer was also able to significantly improve the diagnostic and message information. This results in reduced downtimes, more efficient operation of the machine and a reduction in the workload of the after- sales support.

Thanks to the open system concept of the FMSC safety PLC, further requirements can be implemented easily, flexibly and quickly.

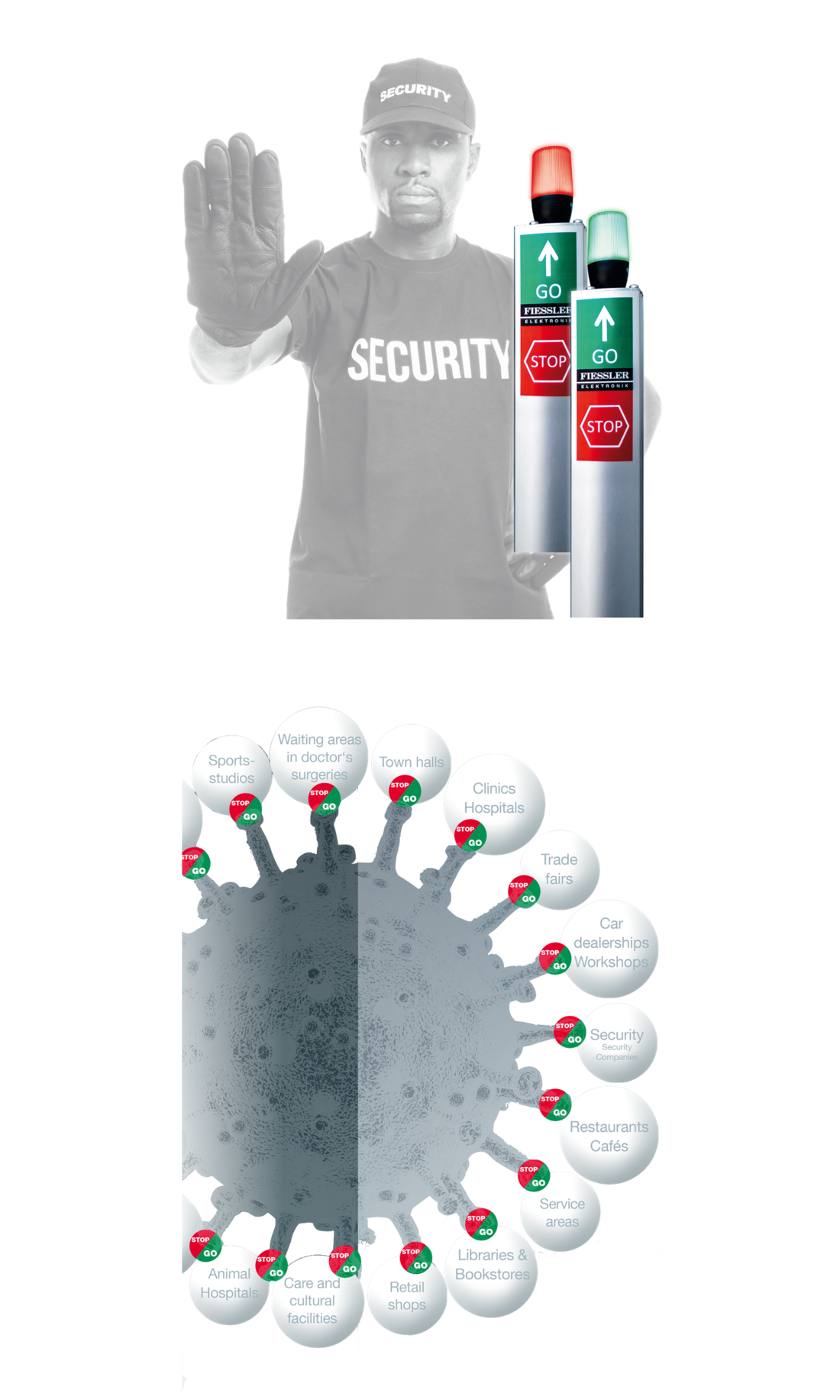

Access control Razl-2CO-person counting in public areas in compliance with the DSGVO

The RAZL-2CO directional pedestrian counter from Fiessler Elektronik is used to monitor and control pedestrian access in public areas such as sales areas, studios, libraries, swimming pools, festivals, concerts, public toilets.

In this context the guard traffic light RAZL-2CO is used as access control or access control to limit the number of persons in an area.

In the current COVID 19 pandemic situation, this access control traffic light prevents that the maximum acceptable number of persons in an area is not exceeded, and thus the necessary safety distance between the persons in this area cannot be maintained. The movement of persons is measured in compliance with the DSGVO. No data is collected or stored with this customer traffic light.

Due to a simple floor mounting with two columns opposite each other and only one connection of the master column to a conventional 230 V socket, the installation of this person counting control is easy and can be carried out without the need for qualified personnel. The configuration of this people counting system is simply done via the app supplied with the device using a smartphone or laptop. Among other things, the maximum permitted number of persons can be entered. If this maximum number is exceeded and/or the number of persons is limited, the access control light switches to red. If the area is entered while the display is red, the acoustic integrated alarm of the access light is triggered and indicates for everyone the violation of the customer number limit.

When leaving the area to be monitored, the respective person is subtracted. Thus, the app always shows the current number of persons in the monitored area and enables an easy to use customer number monitoring.

Through the WLAN connection, further control tasks can be easily solved directly, such as the control of automatic doors or the display of the current number of persons on a monitor in the entrance area.

The watchman traffic light RAZL-2CO can not only be used as access control during the current pandemic, but also for customer counting. In order to control and monitor marketing activities, for example, this device can be used to carry out a customer count or customer number control.

FMSC - Safety control system

The new product video of the Fiessler FMSC safety controller is online.

Experience the advantages of a modern modular

Safety control - Made in Germany

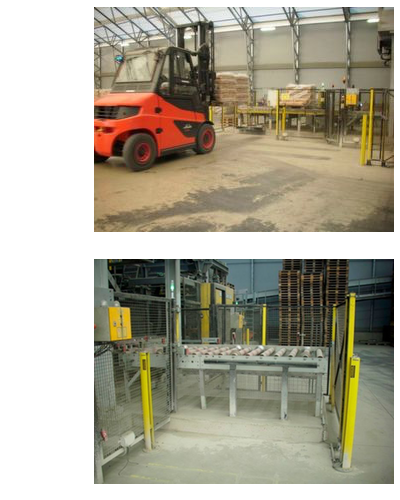

Neues Sicherheitskonzept für Palettierer

Dass Zement alles andere als eine graue Materie ist beweist die Rohrdorfer Gruppe seit Jahrzehnten mit einem breiten Leistungsspektrum.

Der nachhaltige Einsatz von Ressourcen geben den Kunden des Südbayerischen Portland-Zementwerks Geb. Wiesböck & Co., auch bekannt unter dem Namen Rohrdorfer Zementwerk, mit Sitz im Oberbayerischen Rohrdorf, die Gewissheit, stets die richtigen Produkte und den richtigen Partner gewählt zu haben.

Um die Wahl des richtigen Partners ging es auch bei einer bestehenden Anlage, die nicht einfach nur ersetzt, sondern nach neuesten Vorgaben und Normen sicherheitstechnisch auf den Stand der Technik gebracht werden sollte................... weiterlesen!

Das Sicherheitskonzept wurde mit folgenden Komponenten realisiert:

- Sicherheits-Lichtgitter ULVT 800/3 in Schutzsäulen

- Sicherheitssteuerung FMSC

- Sicherheitsrelais FSEM

We have recently added new safe switchgear units to our product range. These are complete in-house developments and of course like all our products Made in Germany. They are supplied complete with connection proposal.

FMSC-STM - Tapis de sécurité - Dispositif d'évaluation

(1) With the electronic switching device FMSC-STM safety contact mats and emergency stops can be retrofitted to an existing system without significantly changing the safety circuit. Furthermore a dead man’s switch can be used for bridging. The device can be configured with or without restart interlock.

FMSC-FP - Safety foot pedal - Evaluation device

(2) With the FMSC-FP electronic switching device, a second foot pedal can be retrofitted easily and cost-efficiently without having to significantly modify the existing safety circuit. The emergency stop function can also be retrofitted using the device. It also provides diagnostic outputs for selector switch, foot switch and relay faults.

FMSC-ESM - Safe Standstill - Evaluation Unit

(3) With the electronic switching device FMSC-ESM, an axis can be safely monitored for standstill. Linear or incremental encoders can be used as sensors. Contactor monitoring and restart interlock can be easy configured, which makes the device very flexible to use.The device can be connected directly or via contactors to the frequency inverter. In addition, an emergency stop circuit can be connected to the device.

BERUFLICHES SCHULZENTRUM AMBERG:

Mittlerweile ist es schon gute Tradition, dass Eberhard Weida und Alexander Berchtold am BSZAM über die Sicherheitstechnik der mittelständischen Firma „Fiessler Elektronik“ referieren. Die mittlerweile über 10-jährige Zusammenarbeit mit dem Familienunternehmen aus Esslingen in Baden-Württemberg stellt für beide Seiten eine "Win-win-Situation" dar.

Die Berufsschülerinnen und -schüler der beiden 12. Klassen der Mechatronik sowie die Schüler der Klasse FSMT1 der Staatl. Technikerschule hatten in den letzten Wochen einen Lernzirkel zum Thema Sicherheitstechnik bearbeitet. Bei den meisten Stationen des Lernzirkels kommen auch Sicherheitsgeräte wie Sicherheitstrittmatte mit Schaltgerät, Sicherheitslichtvorhänge mit Blanking- bzw. Mutingfunktion, Sicherheitslaserscanner oder eine Sicherheitssteuerung aus dem Hause Fiessler zum Einsatz. Deshalb konnten die beiden Referenten auf eine fachkundige Zuhörerschaft bei ihren kurzweiligen Vorträgen bauen.

Zu Beginn der Veranstaltung stellte Herr Berchtold das Traditionsunternehmen „Fiessler Elektronik“ vor. Das Familienunternehmen kann auf eine über 60-jährige Erfahrung im Bereich der optoelektronischen Geräte zurückblicken und hat sich zu einem weltweiten Technologieführer im Bereich der Sicherheitslichtschranken entwickelt. Nach einem Exkurs in die Maschinenrichtline 2006/42/EG erläuterte Herr Weida sehr lebensnah, was bei deren Umsetzung im beruflichen Alltag zu beachten ist. Das Hauptaugenmerk wurde aber nach der Vormittagspause auf die neue modulare Sicherheitssteuerung FMSC gelegt. Weil sich nach einer Livedemonstration der dazugehörigen Programmiersoftware kein Schüler traute, selbst Hand an Maus und Tastatur zu legen, musste ein Lehrer ran. So zeigte Herr Prölß, der die Veranstaltung mitinitiierte, noch einmal, wie intuitiv und einfach die Programmiersoftware „FMSC Studio“ mit Drag and Drop zu bedienen ist. Abschließend erläuterte Herr Berchtold anhand von interessanten Referenzbildern, was beim Einsatz von Sicherheitstechnik noch zu beachten ist.

Fazit am Ende der Veranstaltung: Die für alle Seiten gewinnbringende Zusammenarbeit muss auf jeden Fall weitergeführt werden.

Link zum Downloadformular für die FMSC Studio Demosoftware

1. Programmable safety controller FMSC

Fiessler Elektronik has consequently implemented its more than 60 years of experience and know-how with the new and configurable modular FMSC safety controller. The development not only focused on the high standard of safety but also on how to simply and rapidly implement projects. Miscellaneous functionalities, such as creating combinations, make it easier for the user to program the safety controller. Already created projects can also be comprehensively documented. Rapid response times as well as the safety-oriented monitoring of up to 17 axes round off the profile of the new FMSC safety control.

The modular structure of the FMSC system family ensures that the most efficient hardware solutions will always be found for a monitoring task. The variations Eco, Basic, Advanced and Professional provide a selection of different master devices with a respectively different range of functions. The corresponding functionalities are simply integrated or configured with the programming software, FMSC Studio. The system can be expanded at any time with up to 16 expansion modules. As a result, up to 204 digital inputs and up to 153 digital outputs are available today. And up to 17 axes can be monitored for safety. The compact design makes it easy to integrate the safety control in new systems as well as for retrofitted systems.

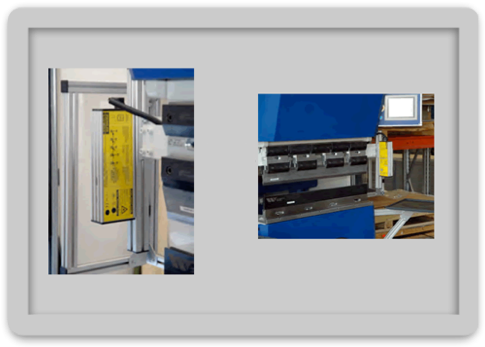

2. Safe operation of a press brake during bending of reflecting or oil-covered material

The sheet metal which is used used on press brakes is very frequently made of stainless steel or V2A steel. However, the sheet metal is covered as a means of protection from corrosion and oxidizing by a thin oil film. In both situations, the sheet metal is characterized by highly reflective and shiny surfaces. In order to provide a safe bending operation of these special materials, the European Standard EN 12622 (Safety of machine tools) requires the use of laser light as light source for a following press brake safety system. Physically, laser light is the only light source emitting parallel lightbeams. Unlike other light emitting sources, the parallel laser light beams prevent the avoidance and non-detection of an obstacle caused by the reflecting objects, such as fingers or hands of the operating personnel. This press brake safety system is fully complying with the requirements of the EN 12622 (Safety of machine tools - Hydraulic press brakes), the new B11.3 (USA), CSA Z.142 (Canada),NR 12 (Brazil) and Japan. The Fiessler press brake safety system AKAS®3 and its laser light beams provide a reliable protection even during bending of reflecting or oil covered materials. The presence of the 3-dimensional laser protective field which is located beneath the upper tool prevents the operator's fingers or hands from being squeezed even under such unfavorable and, at the same time practice- oriented conditions. Thanks to the sequential reduction of the protective field during the closing movement of the press brake, a reliable protection is given during fast speed as well as during slow speed without any loss of productivity. With the help of the fully automatic electromotor driven supports, a safe, simple and operator-friendly adjustment is provided.

3. Press Brakes safety System for compact press brakes

The Fiessler programmable safety center FPSC is an electronic safety controller for personal and machine protection and complies with the highest safety standards: up to safety class 4 according to EN 954-1, SIL 3 according to IEC 61508 SIL3 as well as PL e according to EN 13849.By the use of a safety bus which is available as option, a modular structured system which offers flexibility can be realized, therefore reducing the costly and often elaborate configuration of the safety bus. The simple programming of the FPSC is made via software. No specialized programmer know-how is required. For the connection, i.e. the integration of safe controlling components, various tested and certified software modules are available. The FPSC basic configuration consists of 36 safe inputs and 16 safe outputs. A serial interface transmits the diagnosis data to a superior control unit. More remarkable features of the FPSC are a minimum response time of 1 ms and a high cost/effectiveness.